Two Ply Bellows provides good balance of bellows life spring rate & wider operating range

Two-ply Bellows are the most common type of Pipe bellows , providing a good balance of bellows life, spring rate and a wider operating range.Multi-ply Bellows are made up of two or more concentric tubes made of sheets of metal of a defined thickness. Bellows Systems Two-ply standard bellows designs (02 series Bellows) have been industry standard for over four decades.

If you are unsure of what kind of Multi-ply bellows design is right for you, contact our engineers today and we will provide you with the right bellows for your application. All the Two-ply metal pipe bellows manufactured by Bellows Systems are in accordance with the Expansion Joint Manufacturers Association (EJMA) guidelines.

Bellows Systems can provide Two-ply testable variants as well. We ensure that the bellows are designed in such a way that each ply is capable of handling full line pressure. In the event of failure of the inner ply, the outer ply will last long enough to replace the bellows and reduce any potential down time.

Rigorous testing is performed by Bellows Systems as part of bellows manufacturing process such as low pressure air testing, high pressure hydro tests, fluorescent dye penetrant tests, radiographic tests and helium leak tests. Bellows Systems employs AWS B2.1 certified TIG Welders for custom bellows and AWS D17.1 certified GTAW weld operators for all aerospace bellows.

Call us today or email us at sales@bellows-systems.com to find out more about our Multi-ply Bellows products.

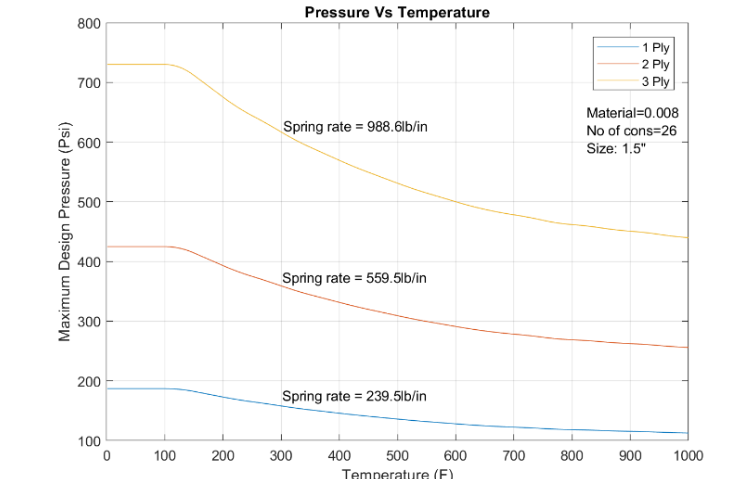

A comparison:

As an example, let us consider two bellows of the same size

Size: 1.5 (in this case)

-

- One made up of a Single ply of 0.008” thick Stainless Steel sheet

- Another made up of 2 plys of 0.008” sheets

From the below graph, we see that the pressure handling capacity increases by 2.2 times. The spring rate is also roughly 2.3 times higher for the Two-ply material.

Another use for designing a Two-ply bellows is to reduce the spring rate at a given overall thickness. However, this does come at the cost of lower pressure handling capacity at any given temperature as shown in the example below.

Need more information?

Download our Data Sheets