Bellows Systems has been manufacturing,

Custom Metal Bellows for the past 40 years

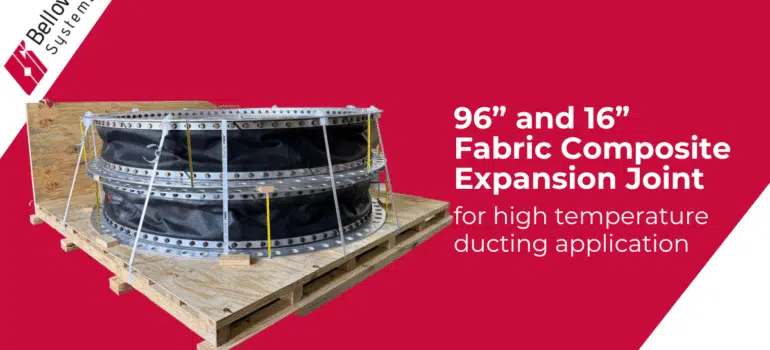

We design and manufacture metal bellows for various industrial OEM applications including, Process Piping Expansion Joints, Actuators and Mechanical Seals, Engine Exhaust Systems and Manifolds, Fluid Management Devices such as Accumulators and Volume Compensators. BSI’s standard metal bellow elements are also readily assembled into various Expansion Joint assemblies per customer requirements. Bellows Systems manufactures Metal Bellows in either Single ply, Double ply (two ply) or Multi ply configurations in a variety of material choices.

Bellows Systems specializes in manufacturing Multi-ply Bellows with high cycle life.

BSI has the state of the art technology to seam welded tubes and form them into bellows configuration with the movements, spring rates and cycle life best suited to your application.

Our Metal Bellows are manufactured using both mechanical punch forming and hydroforming methods. Our punching and roll forming processes allow us to manufacture a variety of shapes including circular, rectangular and even oval shaped bellows in a single or multi-ply configuration. Our Engineers can assist you in finding right bellows design for your application.

Bellows Systems has also been manufacturing Kopperman style hydroformed bellows since acquiring Kopperman Industries in 1986. The choice of materials is dependent on the corrosion resistance required by the operating conditions of the system in which they might be installed.

Want to discuss your requirements with our experts? Call us now

Latest News & Blog