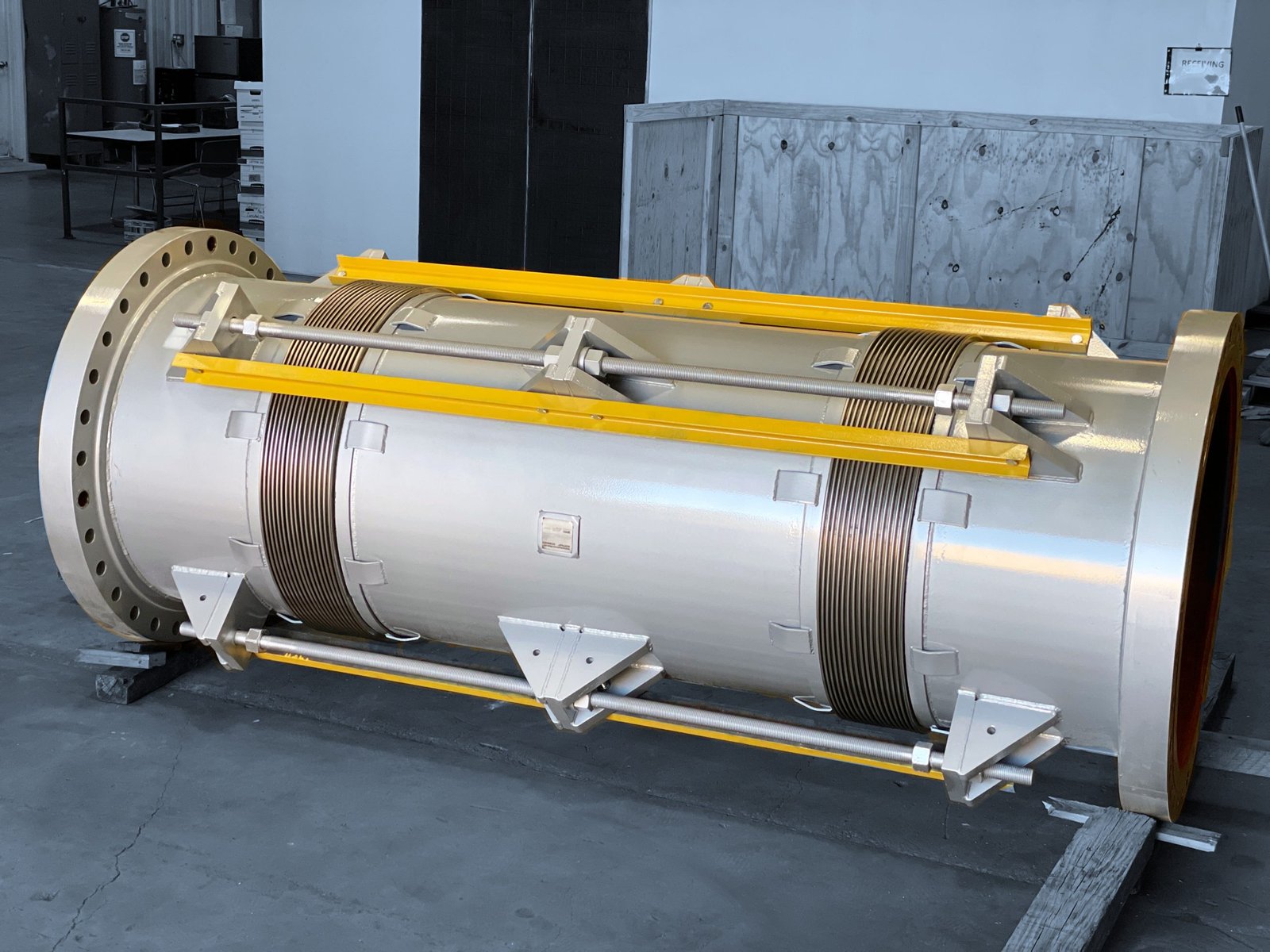

Delivering 12 inch and 20 inch Universal Expansion Joints for the Oil and Gas Company in West Africa

Client Overview

Our client, a major player in oil and petroleum production and storage facilities in West Africa, required reliable expansion joints for a terminal storage tank refurbishment project. The project included (1-off) 12 inch and (2-off) 20-inch universal expansion joints for their critical pipeline system. The project involved accommodating movement, pressure, and thermal expansion in challenging operational conditions. With a focus on durability and corrosion resistance, the client turned to Bellows Systems for a tailored solution.

Project Details

Bellows Systems designed, manufactured, and delivered 12-inch and 20-inch universal expansion joints for the client. These expansion joints were constructed from Alloy 825, a material known for its exceptional corrosion resistance, strength, and durability in demanding environments such as those encountered in the oil and petroleum industries.

The expansion joints also featured ,

- 150# RFSO flanges , both welded

- Bellows Liner – Incoloy 825 ( Alloy 825)

- Bellows Cover – SS304 (ASTM A240)

- Control Rods

The delivered expansion joints were designed to handle:

- Axial, lateral, and angular movements to ensure flexibility and reduce stress on the pipeline system.

- High-pressure and high-temperature environments, typical in oil and petroleum pipelines.

- Corrosive conditions, leveraging the superior material properties of Alloy 825 to ensure long service life.

Why Inconel 825?

Inconel 825 was specifically chosen for this project due to its excellent resistance to corrosion in harsh environments, particularly those involving acidic and oxidizing agents often present in the oil and gas industry. Its robust properties make it ideal for ensuring pipeline safety and efficiency over time.

Key Benefits Delivered

- Enhanced Durability: The use of Inconel 825 ensures the expansion joints withstand corrosive elements, extending their operational life.

- Operational Reliability: Designed to handle complex movements and extreme conditions, the expansion joints optimize pipeline performance.

- Custom Engineering: Bellows Systems provided a tailored solution to meet the client’s unique operational requirements, ensuring seamless integration into the pipeline system.

Client Outcome

The same client previously successfully integrated universal expansion joints into their pipeline system, enhancing both the safety and efficiency of their operations. Impressed by the product quality and engineering expertise, the client awarded repeat order to Bellows Systems for delivering a reliable solution on time and meeting their specific needs.

About Bellows Systems

Bellows Systems has been a trusted partner in delivering high-performance metal bellows and expansion joints for over four decades. Our expertise in custom engineering and advanced material selection ensures that we consistently provide solutions that meet the demanding requirements of industries worldwide.

If you’re looking for a trusted partner for high-performance expansion joints, contact Bellows Systems today!