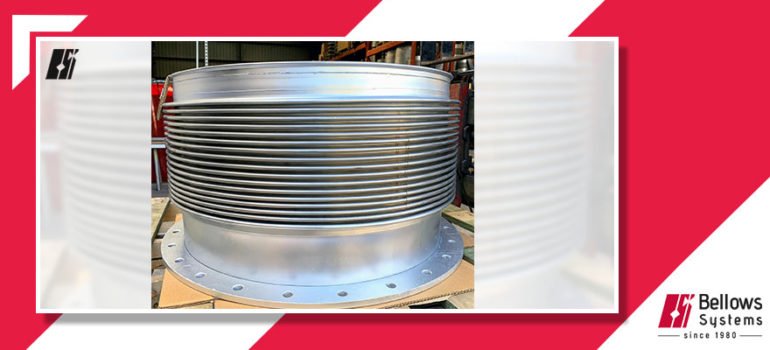

Exhaust compensator for a LPG Tanker

Recently we received an urgent request for replacement of the main engine (MAN B&W 8S35MC) exhaust compensator (bellows expansion joint) for a LPG Tanker en-route to Houston. Bellows Systems designed, fabricated and delivered the replacement 4-ply exhaust expansion joint within 5 days. Drop-off and pick-up was successfully completed during the vessel’s Houston port call.

We also provide quick turn around repair services on exhaust bellows and expansion joints to vessels calling into port of Houston or Galveston.

Make Bellows Systems your go to source for emergency repairs or rebuilds of exhaust bellows and expansion joints. Call us today to find more about our repair services.