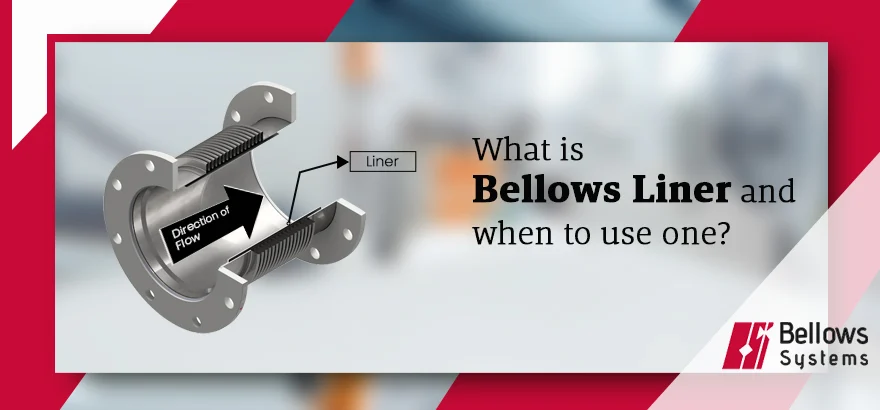

Bellows Liner is an internal sleeve that is used for the following cases,

- To prevent flow induced resonant vibration of bellows due to high flow velocities

- To reduce possibility of erosion from abrasive flow media

- To limit/ minimize the friction losses and create a smooth flow

- To limit/ decrease the surface temperature of the bellows in high temperature applications.

Recommendations for proper design and use of a flow liner?

- The liner material should either be same as the bellows material or suitable for the application.

- When sizing a flow liner proper considerations must be given for the flow velocity, liner length and temperature of the flow media.

- When there is possibility for reverse flow, or bi-directional flow use of telescoping liner is recommended.

- When used in applications with abrasive media use thicker liner material to prevent failure in the liner and exposing the thinner bellows material to erosion.

- When lateral deflection or angular rotation is present, the liner should be designed with sufficient radial clearance to prevent interference with ID of the bellows through the entire movement range.

- When bellows are installed vertically in the direction of the flow, proper drain holes shall be provided on the liner to drain fluid from being trapped.

For our full range of bellows and exapnsions joint products