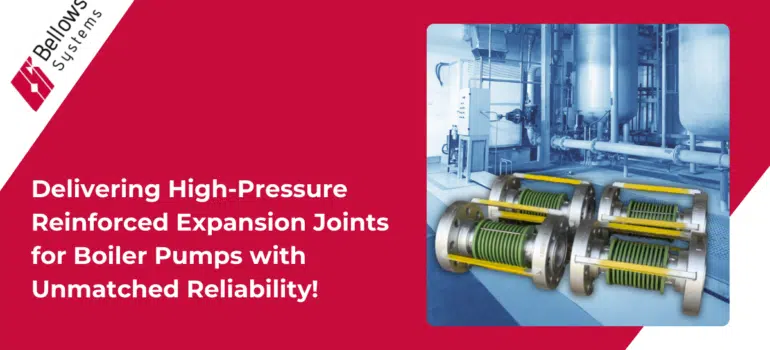

Fabric Expansion Joints: Custom Solutions for Industrial Applications

Fabric expansion joints are essential components designed to manage movement and vibration in various industrial systems. At Bellows Systems, Inc., a leading custom-engineered bellows and expansion joints manufacturer in Houston, Texas, US, we specialize in fabric expansion joints tailored to specific industrial requirements.

Understanding Fabric Expansion Joints

Importance of Fabric Expansion Joints

Fabric expansion joints absorb thermal movements, isolate vibrations, and accommodate misalignment in ductwork and industrial systems, enhancing operational efficiency and system longevity.

Applications Across Industries

- Power Generation: Handling flue gases and air ducts

- Cement Industry: Managing kiln exhausts and dust collection systems

- Pulp and Paper: Accommodating dryer exhaust movements

- Chemical Plants: Dealing with corrosive fumes and high-temperature air

Why Fabric Expansion Joints?

Advantages Over Traditional Joints

Fabric expansion joints from Bellows Systems offer:

- Excellent flexibility and vibration absorption

- Lightweight and easy installation

- High resistance to corrosion and chemicals

- Cost-effective maintenance and replacement

Material Selection for Fabric Expansion Joints

Selecting appropriate materials ensures reliable performance:

- PTFE (Teflon): Outstanding chemical resistance and flexibility, ideal for corrosive environments.

- Fiberglass: Excellent heat resistance and durability, suitable for high-temperature air and flue gas ducts.

- Elastomers (EPDM, Silicone): Provide good flexibility, chemical resistance, and weatherability, perfect for vibration isolation.

For more details, explore our fabric expansion joints product page.

Bellows Systems' Custom Fabric Expansion Joint Solutions

Tailored Engineering

Bellows Systems, Inc. designs each fabric expansion joint solution based on your unique operational conditions, ensuring optimal performance and reliability.

Industry-specific Solutions

- High-Temperature Applications: Custom-engineered fiberglass solutions effectively manage extreme thermal conditions.

- Corrosive Environments: PTFE-lined joints provide superior resistance against aggressive chemicals.

- Flexible Installations: Elastomer-based joints efficiently isolate vibrations, improving overall system stability.

Comprehensive Quality Testing

All fabric expansion joints meet strict quality and performance standards, ensuring safe and effective operation in demanding conditions. Review our detailed engineering standards to learn more.

Benefits of Custom Fabric Expansion Joints

- Reduced vibration and noise

- Enhanced operational efficiency

- Lower maintenance costs

- Increased equipment lifespan

Frequently Asked Questions

When should I choose fabric over metal expansion joints?

Fabric joints are preferable when lightweight, flexible vibration absorption and corrosion resistance are priorities, especially in low-pressure air or gas systems.

When should I choose fabric over metal expansion joints?

Fabric joints are preferable when lightweight, flexible vibration absorption and corrosion resistance are priorities, especially in low-pressure air or gas systems.

What maintenance do fabric expansion joints require?

Minimal regular inspections for wear and tear are recommended. Fabric expansion joints from Bellows Systems generally require very low maintenance.

Are fabric expansion joints durable enough for harsh industrial environments?

Yes. Our fabric joints use high-grade materials engineered specifically to withstand harsh conditions, including extreme temperatures and corrosive environments.

For additional details about our industry-specific solutions, visit our applications page.

Ready for a Customized Fabric Expansion Joint Solution?

Consult with Our Experts Today!

Choose Bellows Systems, Inc.—your trusted custom-engineered bellows manufacturer in Houston, Texas, US—and get precisely engineered fabric expansion joint solutions tailored for your specific industry and operational needs.